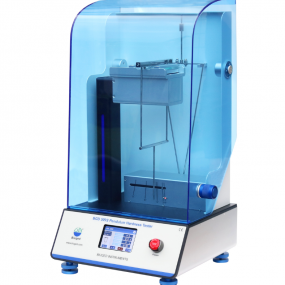

Multi-functional Cyclic Corrosion Test Cabinets BGD 885/1

-

175

-

0765 259 545

Model: BGD 885/1

Model: BGD 885/1

ISO DIN EN 16151 《Corrosion of Metals and Alloys - Accelerated Cyclic Tests With Exposure to Acidified Salt Spray, ''dry'' and ''wet'' Conditions》

ISO 16701 《Corrosion of metals and alloys -- Corrosion in artificial atmosphere -- Accelerated corrosion test involving exposure under controlled conditions of humidity cycling and intermittent spraying of a salt solution》

|

Ordering Information → |

BGD 885/1 (Salt fog spray) |

BGD 885/2 (CCT/Salt fog spray+dry+100% humi.) |

BGD 885/3 |

|

Working Room Size(W×H×D) |

1140mm×760mm×700 mm |

||

|

Working Room Capacity (no including V shape cover) |

600 L |

||

|

Overall Size(W×H×D) |

1780mm×1080mm×1250mm |

||

|

Salt Solution Reservoir |

120 L (External) |

||

|

Temperature Range(Salt Fog) |

RT~60℃ |

||

|

Temperature Range(Humidity) |

--- |

RT+5℃~60℃ |

RT+5℃~60℃ |

|

Temperature Range (Dwell/without forced air) |

RT~60℃ |

||

|

Temperature Range (Dry-off/with forced air) |

--- |

RT~70℃ |

RT~70℃ |

|

Humidity Range |

--- |

95%~100% |

20%~100% |

|

Max. Specimen Panel Capacity (15cm×7cm) |

160 pcs(10 panel racks×16 slots ea) |

||

|

Hanging Rods |

6 pcs(length 80cm) |

||

|

Collectors |

2 |

||

|

Salt Solution Consumption |

(12~15)L/d |

||

|

Compressed Air Requirement |

(4~8)bar,flow rate≥28L/min |

||

|

Supply Water Requirement |

High Purity Deionized Water,conductivity ≤0.1uS/cm |

||

|

Power Supply |

AC (220±10)V ,50/60Hz,Max. current 16A |

||

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR