FNCT Full Notch Creep Tester

-

528

-

0765 259 545

FNCT Full Notch Creep Tester

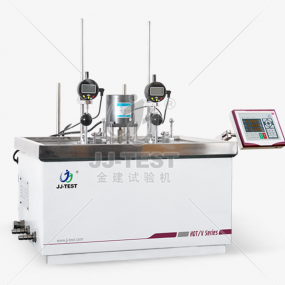

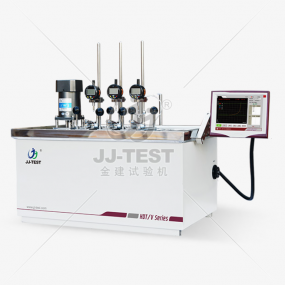

This instrument is mainly used to test polymer materials, especially special materials for water supply and gas polyethylene pipes, in a specific temperature or solution, and record the breaking time under static tension to determine the material's resistance to slow crack growth. It can also be used for pipe drawing. Pull performance test. The machine has stable performance and is exported to European and American markets. Test method: ①Tensile creep test ②Full-notch tensile creep test ③Pull-out test

This instrument is mainly used to test polymer materials, especially special materials for water supply and gas polyethylene pipes, in a specific temperature or solution, and record the breaking time under static tension to determine the material's resistance to slow crack growth. It can also be used for pipe drawing. Pull performance test. The machine has stable performance and is exported to European and American markets. Test method: ①Tensile creep test ②Full-notch tensile creep test ③Pull-out test

FNCT Full Notch Creep Tester

Model: FNCT

Standard: GB/T 32682GB/T 15820GB/T 11546ISO 16770ISO 899ISO 3501

Technical Parameter

Number of test stations:6

Constant load force range: 20N - 5000N

Force accuracy: ±1% (Has self-calibration function )

Effective stretch stroke: (0 - 200)mm

Temperature control range:n RT -95℃, 15℃ - 95℃

Temperature control accuracy: ±0.5℃

Test medium: Water or active agent solution

Media tank volume: 120L

Number of test stations:6

Constant load force range: 20N - 5000N

Force accuracy: ±1% (Has self-calibration function )

Effective stretch stroke: (0 - 200)mm

Temperature control range:n RT -95℃, 15℃ - 95℃

Temperature control accuracy: ±0.5℃

Test medium: Water or active agent solution

Media tank volume: 120L

Product Similar

JJPOT Pipe Opacity Tester

This instrument is mainly used to determine the opacity of pipes and fittings.The JJPOT Pipe opacity tester overcomes the subjectivity of traditional methods to test the opacity of pipes, and then obtains the true transmittance of tpipes. It consists of optical source, Luminous flux collection system, automatic specimen going in/out controlling system, specimen automatic moving device, specimen support, man-machine communicating touch screen and micro-printer.

Standard: GB/T 21300; GB/T 18742;; ISO 7686

0765 259 545

Mainly used for the determination of the thermal deformation temperature and Vicat softening point temperature of non-metallic materials such as plastics, hard rubber, nylon, electrical insulating materials, long fiber reinforced composite materials, high-strength thermosetting laminates, etc. Convenient operation, precise control, and extremely intelligent.

0765 259 545

MFI-1312 Melt Flow Indexer

Model: MFI-1312

Manufacturer: JJ Test - China

Contact for quotation: 0765 259 545

This instrument is used to test the engineering plastics such as polyethylene, polysulfone, fluoroplastics and nylon with high melting temperature, as well as plastics with low melting temperature such as polyethylene, polystyrene, polypropylene ABS resin and polyformaldehyde resin.

0765 259 545

Standard GB/T 8802, GB/T 5836.1, GB/T 20221, GB/T 18993, GB/T 1634, GB/T 1633, GB/T 10002, ASTM D 648, ASTM D 1525, ISO 306, ISO 75, ISO 2507

0765 259 545

JJPDTM-112 Pipe Fittings Valve Pressure Drop Testing Machine

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR