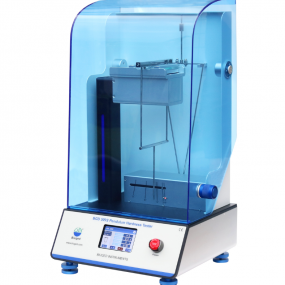

BGD 632 Precise Rub Resistance Tester

-

152

-

0765 259 545

Precise Rub Resistance Tester

Model: BGD 632

BGD 632 Precise Rub Resistance Tester is designed and manufactured according to ASTM D 5264 and TAPPI T 830 . It is applicable in abrasion resistance test of printed materials like labels, folding cartons, corrugated boxes, inserts, circulars, and other packaging materials having applied graphics on a flat substrate. It can help users to analyze the affairs of lower abrasion assistance, ink layer falling-off, lower printable of PS boards, and rigidity of coating layers of other products.

Model: BGD 632

BGD 632 Precise Rub Resistance Tester is designed and manufactured according to ASTM D 5264 and TAPPI T 830 . It is applicable in abrasion resistance test of printed materials like labels, folding cartons, corrugated boxes, inserts, circulars, and other packaging materials having applied graphics on a flat substrate. It can help users to analyze the affairs of lower abrasion assistance, ink layer falling-off, lower printable of PS boards, and rigidity of coating layers of other products.

Precise Rub Resistance Tester

Model: BGD 632

Model: BGD 632

Characteristics

◆ Applicable in dry or wet rubbing or scuffing, wet bleed, transfer, wet smear and functional tests.

◆ Arc moving model, double testing station, high efficiency

◆ Manifold speeds, convenient and flexible.

◆ Micro computer controls, film front control panel

◆ LCD displays testing data

◆ Function of memory when power off, buzzer prompts automatically when test is finished.

◆ By test, controls production technique efficiently, avoids loss of goods returns caused by bad quality.

◆ The specimen's coating and receptor rub each other under specified speed and pressure load. Determine the abrasion of coating or ink layer by test the decrement of coating concentration or decrement of coating thickness.

Main Technical Parameters:

■ Rubbing pressure:8.9N (2lb),17.8N (4lb)

■ Rubbing speed: 21, 42, 85,106 cpm

■ Rubbing motion: to-and-fro arc motion

■ Rubbing times: 0~999,999

■ No. of specimens: 1~2 pieces

■ Dimension: 485 mm (W)×390 mm (D)×230 mm (H)

■ Power: AC 220V 50Hz/60Hz

■ Net weight: 40KG

■ Standards:ASTM D5264 TAPPI T830

■ Configuration Standard: Mainframe, test block 8.9N (2lb),test block 17.8N (4lb), Rubbing pad

■ Optional:Non-standard test block

■ Ordering Information:BGD 632---Precise Rub Resistance Tester

■ Rubbing pressure:8.9N (2lb),17.8N (4lb)

■ Rubbing speed: 21, 42, 85,106 cpm

■ Rubbing motion: to-and-fro arc motion

■ Rubbing times: 0~999,999

■ No. of specimens: 1~2 pieces

■ Dimension: 485 mm (W)×390 mm (D)×230 mm (H)

■ Power: AC 220V 50Hz/60Hz

■ Net weight: 40KG

■ Standards:ASTM D5264 TAPPI T830

■ Configuration Standard: Mainframe, test block 8.9N (2lb),test block 17.8N (4lb), Rubbing pad

■ Optional:Non-standard test block

■ Ordering Information:BGD 632---Precise Rub Resistance Tester

Product Similar

BGD 746 Super High Speed Dispersing Machine integrates super high-speed dispersion, stirring and automatic control of lift distance. It can meet the application requirements of customers for super high-speed dispersion and homogeneous emulsification, with the excellent dispersion and emulsification effects, as well as high dispersing efficiency. In addition, this machine is operated by a large-size touch screen, which is powerful, convenient and practical.

Features

◆ Super high-speed motor: The max. speed can reach 20,000 r/min. Bigger torque, lower noise and lower power consumption.

◆ The max. lift distance can reach 300mm. Servo system for locating can precisely feedback the height information in real time.

◆ Dispersing blade can be set to stay at the required height, which is suited to different sizes of dispersing containers or different material levels. At the same time, the use safety can be improved.

◆ In the whole dispersing process, the dispersing blade can stir circularly between the set upper and lower limit. The lift distance and speed can also be set. Greatly improve the dispersion efficiency.

◆ With the 7-inch touch screen, the tip speed, torque ratio and the height of dispersing blade can be displayed in real time.

◆ Test parameters can be set, such as speed, run time, diameter, height, etc.

◆ Suitable for containers with the capacity of 0.5L-5L, and can meet more different test requirements.

0765 259 545

A pendulum resting on a coating surface is set into oscillation and the time for the oscillation amplitude to decrease by an amount specified in this International Standard is measured. The shorter the damping time, the lower the hardness.

Two test procedures are considered in some detail, namely those of König and Persoz.(The Persoz and König methods differ by the period and amplitude of the oscillation. The Persoz test measures the time taken for the amplitude of oscillation to decrease from 12° to 4°; the König from 6° to 3°.)

The instruments embody the same principle — that the amplitude of oscillation of a pendulum touching a surface decreases more rapidly the softer the surface — but differ in respect of dimensions, period and amplitude of oscillation.

BGD 509/S Pendulum Hardness Tester is the newest product which can be used in accordance with the following National and International Standards: ISO 1522, ASTM D4366,BS 3900-E5,DIN 53157,NBN T22-105,NF T30-016.

It’s a simple to use instrument and can be supplied in one of three model types: Persoz, König, and Persoz and König combined

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR