Ink Abrasion Teste BGD 626

-

176

-

0765 259 545

Ink Abrasion Tester

Model: BGD 626

Manufacturer: Biuged - China

BGD 626 Multi-section Ink Proofing Press is the newest product used for the testing the adaptability of ink printing. Compared with other types, it has many features as below:

◆ Distribute ink automatically and time and speed for distributing ink are adjustable.

◆ Used for lithography printing,letterpress printing or UV ink, UV flexographic ink

◆ Printing pressure and printing speed can be set according to the user’s requirments.

◆ Can print different substrates,such as book paper, art paper,matt art paper, gray paperboard,film and tinplate etc.

◆ High repeatability and reproducibility.

◆ High quality, easy to clean and maintenance, simpe and safe for operation.

Model: BGD 626

Manufacturer: Biuged - China

BGD 626 Multi-section Ink Proofing Press is the newest product used for the testing the adaptability of ink printing. Compared with other types, it has many features as below:

◆ Distribute ink automatically and time and speed for distributing ink are adjustable.

◆ Used for lithography printing,letterpress printing or UV ink, UV flexographic ink

◆ Printing pressure and printing speed can be set according to the user’s requirments.

◆ Can print different substrates,such as book paper, art paper,matt art paper, gray paperboard,film and tinplate etc.

◆ High repeatability and reproducibility.

◆ High quality, easy to clean and maintenance, simpe and safe for operation.

Ink Abrasion Tester

Model: BGD 626

Manufacturer: Biuged - China

Model: BGD 626

Manufacturer: Biuged - China

■ Effective size of Coloured Strips:106mm×215mm(two colours);106mm×215mm/45mm×215mm(three colours);45mm×215mm(four colours)

■ Printing Rubber:Common rubber or special rubber for UV ink (either-or)

■ Speed of Distributing Ink:There are three different speeds (550,700,900 rpm)on the control board.Operator also can dismantle shell of machine to do stepless speed regulation.

■ Printing Speed:There are three different speeds (10,16,22 rpm)on the control board.Operator also can dismantle shell of machine to do stepless speed regulation.

■ Distributing Ink Time:1~120 second (adjustable)

■ Print Pressure:Can be adjusted precisely externally according to the substrate thickness(±0~800g)

■ Distributing Ink Pressure:Can be adjusted precisely externally according to the rubber using status

■ Power Supply:AC 220V/50HZ;Power:250W(saving electrical power design)

■ Dimensions of Machine:525mmX430mmX280mm

■ Weight:75KG

■ Ordering Information:BGD 626---Multi-section Ink Printing Proofer

Product Similar

Multi-functional Cyclic Corrosion Test Cabinets

Model: BGD 885/1

0765 259 545

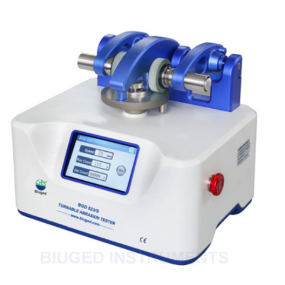

BGD 630 Rub Resistance Tester

Model: BGD 630

BGD 630 Rub Resistance Tester is applicable in rub abrasion resistance test of printing works, light sensitive layer of PS boards, and coating layers of relative products. It can help users to analyze the affairs of lower abrasion assistance, ink layer falling-off, lower printable of PS boards, and rigid of coating layers of other products.

◆ Wide voltage range design(110-220V;50/60Hz), good compatibility

◆ Adjustable variable speed:5~95 c.p.m(stepless speed regulation)

◆ Micro-computer control, LCD displays data.

◆ Parameters set freely and permanently storage.

◆ Control and resolve the problems of low bad abrasion resistance and easy falling-off of ink layer

of printing works.

◆ By test, controls production technique efficiently, avoids loss of goods returns caused by bad quality.

◆ The specimen's coating and receptor rub each other under specified speed and pressure load. Determine the abrasion of coating or ink layer by testing the decrement of coating concentration or decrement of coating thickness.

0765 259 545

Precise Rub Resistance Tester

Model: BGD 632

BGD 632 Precise Rub Resistance Tester is designed and manufactured according to ASTM D 5264 and TAPPI T 830 . It is applicable in abrasion resistance test of printed materials like labels, folding cartons, corrugated boxes, inserts, circulars, and other packaging materials having applied graphics on a flat substrate. It can help users to analyze the affairs of lower abrasion assistance, ink layer falling-off, lower printable of PS boards, and rigidity of coating layers of other products.

0765 259 545

Wet Abrasion Scrub Tester with Image Recognition

Introduction: For the scrub resistance of wall paints and related products, operator should record the number of cycles to remove one continuous thin line of paint film across the 12.7mm(1/2 in.)width of the shim. But how to judge this 12.7mm length accurately? different operators always have their different judging standards. To accurately and quickly determine the end point of the test, it is not only necessary for the operator to have a preliminary prediction of the cycles of scrub resistance of the test samples, but also for them to be able to accurately identify the length of the removed paint film. However, it is quite difficult in actual operation.

0765 259 545

Dial Reading Rotary Viscometer

Model: BGD 151/1

Dial Rotary Viscometer is used in measuring viscosity friction and absolute viscosity of liquid. It has four rotors of NO.1-4 which can be chosen to be in accordance with the viscosity of the liquid and the rotation speed. It is widely used to determine viscosity of various liquids such as oil, paint, plastic, food, medicine, adhesive, etc. It is widely applied in the field of petroleum chemistry, medicine, food, light industry, textile industry, scientific research, etc

0765 259 545

This is the newest type Shore hardness meter in the market, which is used for Shore hardness testing with pocket size model and integrated probe. With RS 232 interface and can be switched off automatically. The meter screen can show hardness result, average value, max. value directly.

Standards: DIN53505, ASTMD2240, ISO7619, JISK7215

For getting a stable and accuracy reading, operator can choose a special holder while measuring. This holder can give a enough force through weights of meter pressing needle , thus ensure the meter foot could press on the sample completely.

0765 259 545

These newest stirrers are of the highest quality. The core a direct current brushless motor is explosion-proof and overcomes the disadvantages of traditional stirrers. The stirrers can operate under high load for an extended period of time without any need for maintenance.

Features:

◆ High reliability and outstanding performance.

◆ LCD display for precise monitoring of set and actual speeds, a wide range of speed from 50 to 2200rpm with control accuracy of ±3rpm(BGD 702&BGD 704&BGD 706).

◆ Brushless DC motor for long life, maintenance free and explosion proof Torque trend display for real-time information on viscosity changes.

◆ Safety circuits allow for safe stop function in anti-stall or overload conditions.

◆ Smooth operation prevents accidental spillage and splashing.

◆ Provides constant speed even with changes in viscosities of the samples.

◆ Remote function provide PC control and data transmission

◆ Availability of auto-restart function in case of power loss for overnight operations.

0765 259 545

Automatic Cross Hatch Tester BGD 535

As an important method to evaluate the adhesion degree between coating and substrate, cross cut method has been widely used. Although the traditional manual cross cut method is simple and convenient, due to the operator's cutting speed and coating cutting force can not be accurately controlled, the test results of different testers are different. The latest ISO 2409-2019 standard clearly defined that in order to obtain uniform and consistent cutting, automatic cross hatch adhesion tester with motor drive shall be used as far as possible.

0765 259 545

Precise Oven

BGD Series Precise Ovens with forced convection focused on addressing the requirements involved in drying or heating samples. With high quality and reliability, high cost performance, outstanding temperature accuracy, Biuged brand ovens has become the first option for many laboratories.

Features:

◆ Microprocessor PID temperature controller with temperature control protection, digits display and timing function ensures a precise and reliable temperature control.(intelligent programmable LCD temperature controller is an option)

◆ Hot-air circulating system consists of a fan keeping running under a high temperature and proper air ducts to ensure a uniform distribution a high temperature in chamber

◆ Independent alarm system for temperature-limiting ensures experiments run safely and no accident would happen.(Option)

◆ Recorder and printer are options which can print or record set parameters and trace variation curves of temperature.(Option)

◆ Can equip explosion-proof or vacuum (Option)

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR