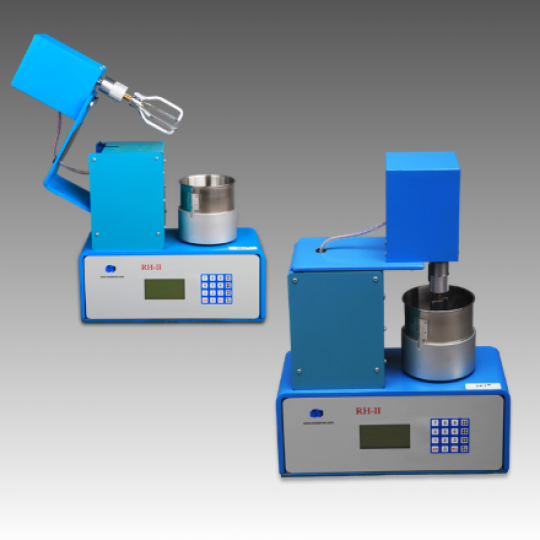

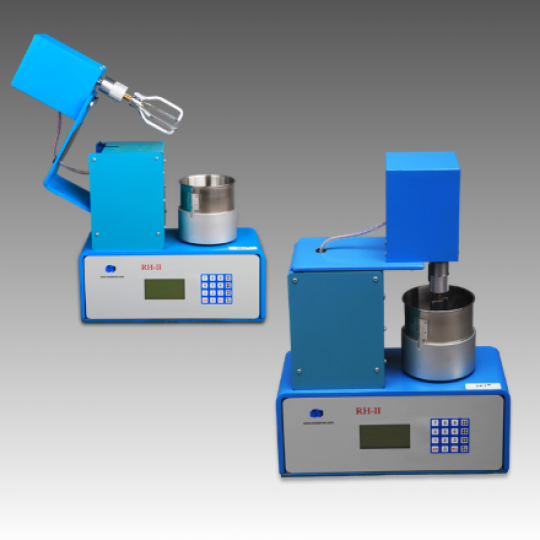

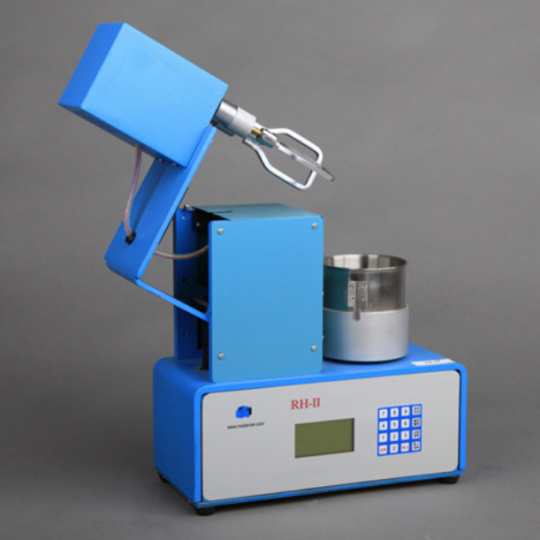

Digital Emulsification Tester

-

148

-

0765 259 545

Product Number: RH-Ⅱ

Brand Name: MODERNER

Product Origin:China

Introduction:

RH-Ⅱ Digital Emulsification Tester is matching for ASTM D 4942, it is a special equipment for quick testing water demand of offset printing ink and vehicle. The machine adopts double frame-type planetary stirring way. The shear force and disperse decrease the particle size (not mutual solvent liquid) into desired fineness. The products remain flowable so as to get homogenous emulsifying state. The machine adopts programmable control, liquid crystal screen display running parameters & operating mode. It features simple structure、reliable performance、flexible operation. If a customer has a special demand for revolution of stirring paddle, the instrument can be customized by modifying programmable parameters according to order.

Product Number: RH-Ⅱ

Brand Name: MODERNER

Product Origin: ChinaStandard: ASTM D4942

Contalner speed: 4.5±5rpm

Electrical Source: 220V 50Hz

Overall Dimension: 330×150×460mm

Packing size: 590×450×350mm

Weight: 20kg

Gross weight:24.2kg

Operating Procedure:

1.Operation:

(1)Put the instrument on the flat、stable platform, plug in, turn on the power switch which is on the back & next to socket, liquid crystal screen displays initialization information.

(2)A stirring paddle can be lifted up so as to easily replace it and easily take down a container & put it on. When stirring paddle is revolving, if not cautiously lifting it up, the instrument will automatically stop running; After replacing, if need resume running, push “Run” again.

(3)When dissambling stirring paddle, first moving down knurled sleeve of stirring paddle’s handle, then moving down stirring paddle. When installing a stirring paddle, please pay attention to notch which is on the stirring shaft and in the middle of hole of stirring paddle’s handle. First, first moving down knurled sleeve of stirring paddle’s handle, insert stirring paddle’s handle into stirring shaft, swing slightly so as to face notch position and resume knurled sleeve to original position.

(4)Before turn on the instrument, make sure that a stirring paddle has been correctly set up in position and a stirring paddle doesn’t touch a container. After turn on the instrument, a stirring paddle & a container simultaneously start revolving until reaching setting number, the instrument automatically stop running.

(5)After finishing running, the instrument have to be cleaned up, turn off the power switch which is on the back & next to socket.

2. Operation for Control Panel:

(1) When switch-on, buzzer makes ticking sound, it shows that self-checking of the instrument is normal.

(2) Then liquid crystal screen displays initialization information.

(3) When liquid crystal screen enters into operating interface display, showing the following information:

“Run Speed: 90 r/min”

“Set Cycle: ”

“Run Cycle: 0000”

“Frequency: 00”

(4) The instrument gives tacit consent to 90 r/min. If changing speed, push “Speed”, speed can be loop-switched among 100、150、90.

(5) Switch-on the instrument, first running cycle should be setted. Slightly push number key which is on the keyboard so as to set running cycle. Inputted “Set Cycle” must be four digit, not enough four digit, fill up “0” in front. If need running cycle 500, “0500” should be inputted. If found inputting incorrectly, push “Reset” to cancel current inputting.

(6) If inputting “Set Cycle”, push “Run” to switch-on operation. Stirring paddle rotates per cycle, “Run Cycle” automatically add 1. When “Run Cycle” reaches “Set Cycle”, the instrument automatically stop running, buzzer makes ticking sound, at the same time “Frequency” automatically add 1, clear “Run Cycle” to get ready for next counting.

(7) If push “Stop” during operation, the instrument immediately stop running, but reserve the number of “Set Cycle”、“ Run Cycle” and “Frequency”. If continuously running, push “Run”, the instrument resume running until reaching setting cycle.

Push “Clear”、“ Renew”, separately eliminate the number of “Run Cycle”、“ Frequency”.

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR