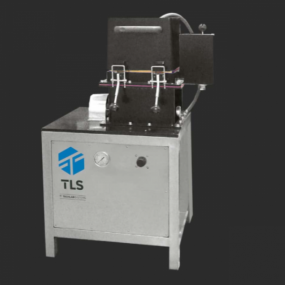

MiniVAL Carton Compression Tester

-

601

-

0765 259 545

MiniVAL Carton Compression Tester

Standard : UNE 137001 - DIN UNE EN ISO 12048 - DIN UNE EN ISO 16495 - ASTM D 642 - ASTM D2659-16, ASTM D 4169, ASTM D 4577 - ASTM D 7030 - DIN 55440-1 - TAPPI T804 - FEFCO 50 - 49 CFR 178.606 - ISTA Series…

Standard : UNE 137001 - DIN UNE EN ISO 12048 - DIN UNE EN ISO 16495 - ASTM D 642 - ASTM D2659-16, ASTM D 4169, ASTM D 4577 - ASTM D 7030 - DIN 55440-1 - TAPPI T804 - FEFCO 50 - 49 CFR 178.606 - ISTA Series…

MiniVAL Carton Compression Tester

- Maximum force scale: 10 kN (1000 kgf)

- Force accuracy: 03 high-precision force sensors (prevents unilateral load error), accuracy 0.03% FS.

- Force resolution: 0.1 N

- Compression plate size: 500 x 500 mm

- Maximum compression stroke: 500 mm

- Drive system: DC variable speed drive system

- Measurement system resolution:

- Force resolution: 0.1 N (0.02 lbf.)

- Displacement resolution: 0.001 mm (0.000040 in.)

- Speed: 0.1 mm/min (0.0040 in./min.)

- Flatness of compression plate: 0.25 mm (0.01 in.)

- Parallelism of compression plate: ±1 mm (±0.04 in.)/meter

- Safety feature: E-Stop

- Overload protection in software

- Safety switches for upper and lower limits

- Communication error detection with automatic stop

- Test speed: 1 - 350 mm/min (0.04 - 13.78 in./min.)

- Roller retract speed: 350 mm/min (13.78 in./min.)

- Equipment mounted with silent shock-absorbing and anti-vibration blocks.

- Output interface: RS-232

- Units: Force in Newton, Kg & Pound; Displacement in mm & inch

- LYNX software for compression testing + LYNX management module with basic statistics, PC-controlled, including 3 test modules:

- BCT Test Module (Standard Test)

- Constant load (Stacking test)

- Cycle test module (Deformation and force)

- LYNX management software module with basic statistics allows management of generated data, language selection, report preparation and printing (customizable with logo), unit changes, user accounts and passwords, minimum, maximum, and optimal values for data management through statistics, charts, GAUSSEN Bell, tolerance comparison, and data export to Word, Excel, PDF, and more.

- Dimensions: 800 x 600 x 1050 mm

- Power supply: 220V 50Hz

- Weight: 200 kg

Product Similar

Pulp Disintegrator PD-10

- Compact and sturdy.

- Electronic components are protected and located at the top of the device.

- Safety mechanism with an additional stop button.

- Tilted head and easy to clean.

- Preselection of revolutions via digital display.

- Speed: 2,975 ± 25 rpm.

- High-performance motor.

- Disintegration vessel made of stainless steel.

- Disintegration vessel capacity: 2 liters.

- Digital display.

- Easy to use and highly convenient.

- CE marked.

- Standards: ISO 5263, NF Q 50002, PAPTAC C.6, SCAN C 18/M2, TAPPI T205, UNE 5263-3:2005

0765 259 545

Somerville Fractionator SF-10

PAPTAC C.11P, TAPPI T275 , TAPPI UM 242.

0765 259 545

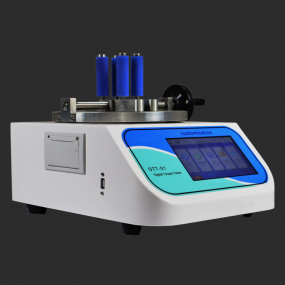

Digital Torque Tester DTT-01

- Standards : ASTM D2063, ASTM D3198, ASTM D3474

- Description

DTT-01 Digital Torque Tester is one professional testing instrument for determination of application torque and removal torque of bottle caps.

0765 259 545

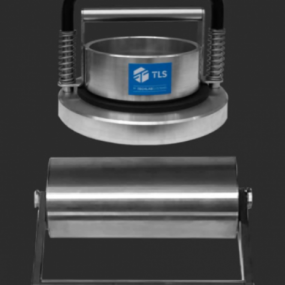

Compresometro de Muestras CDM-5

Standard: ISO 13820

- ECT test : APPITA/AS 1301.444s, DIN EN ISO 3037, FEFCO 8, ISO 13821, SCAN P33, TAPPI T 811, TAPPI T 823, TAPPI T 838, TAPPI T 839

- FCT test : APPITA/AS 1301.429s, DIN EN ISO 3035, FEFCO No. 6, SCAN P32, TAPPI T 825

- RCT test : APPITA/AS 1301.407s, ISO 12192, SCAN P34, TAPPI T 822

- CMT test : APPITA/AS 1301.434s, ISO 7263, SCAN P27, TAPPI T809

- CCT test : SCAN P42, TAPPI T 843, UNE ISO 16945

- PAT test : APPITA/AS 1301.430s, FEFCO No. 11, TAPPI T 821

0765 259 545

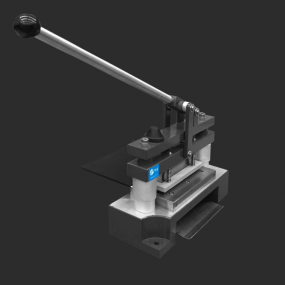

Digital Micrometers M5 Series

- Operated manually with a convenient rotating handle.

- Digital display with reset function to zero.

- Sturdy and user-friendly design.

- Probe area: 2 cm² / 10 cm² (depending on model).

- Reading resolution: ± 0.01 / ± 0.001 mm (depending on model).

- Measurement range: 0 to 10 mm (Paper) – 0 to 15 mm (Cardboard).

- Probe pressure on sample according to corresponding standards.

- Compatible with the T-LAB Laboratory Management System.

- CE marked.

0765 259 545

Applications

Paper. Folding carton. Corrugated board. Plastic film.Flexible packaging.

Description

Electromechanical one column material testing machine designed to perform tensile, compression, bending, shearing, peeling test of very light materials up to 1 kN.

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR