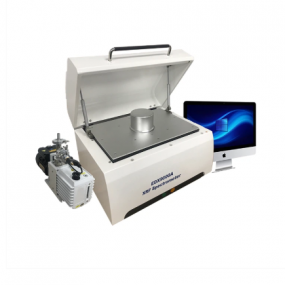

Bench Top XRF Oil Element Analyzer- EDX-9000E

-

165

-

0765 259 545

Features and Benefits

•Rugged elemental analyzer for repeatable and reproducible results in laboratories

production environments

• Intuitive interface is displayed on the large, industrial touchscreen.

• Streamlined software and one-touch measurement start makes it easy for any operator

to get high quality results.

• Training for routine analysis takes only minutes.

• Atmospheric compensation allows analysis without the need for helium or vacuum purge,

minimizing the cost per analysis.

• Automatic carbon/hydrogen (C/H) ratio correction allows the analysis of multiple types of

oils and fuels to be made on a single calibration, simplifying analyzer setup and operation

• X-ray tube and detector are operated in conditions designed to ensure long-term reliability.

• Built for tough environments.

• On-board data storage of up to 100,000 results, including spectra

• Low cost of maintenance

Specifications

|

Detector |

High Resolution SDD |

|

Excitation Source |

50 watts high efficiency Ag/Rh tube 50kv Max,1000Max |

|

Working temperature |

-20 to 50 °C |

|

Measuring time per sample |

30-130 seconds |

|

Sample Type |

Liquid, powders and solids |

|

Factory Calibration |

Low sulfur: 10ppm- 100ppm High sulfur: 0.01%-5% |

|

Detection Limit of Sulfur |

3ppm |

|

Instrument Dimension |

380×372×362mm(L*W*H) |

|

Weight |

30 kg |

|

External Connection |

USB Port |

|

Test Report |

Excel, PDF |

|

Spares and Consumables |

Sample test Mylar Oil analysis sample cup Sampling spoon Test window film |

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR