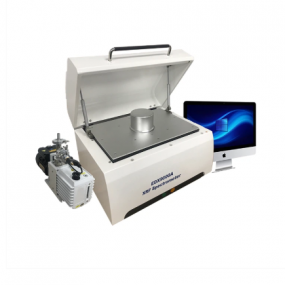

EDX-8800G MAX XRF Spectrometer Floor-standing X-ray Fluorescence

-

104

-

0765 259 545

EDX-8800G MAX XRF Spectrometer Floor-standing X-ray Fluorescence

Model: EDX-8800G MAX XRF

EDX-8800G MAX XRF Spectrometer Floor-standing X-ray Fluorescence Spectrometer Simply the Best The latest generation of detector: High-throughput count rate and ultra-low resolution. Wider element detection range: Analysis covers elements from 9F (Fluorine) to 95Am (Americium) in the periodic...

Model: EDX-8800G MAX XRF

EDX-8800G MAX XRF Spectrometer Floor-standing X-ray Fluorescence Spectrometer Simply the Best The latest generation of detector: High-throughput count rate and ultra-low resolution. Wider element detection range: Analysis covers elements from 9F (Fluorine) to 95Am (Americium) in the periodic...

EDX-8800G MAX XRF Spectrometer Floor-standing X-ray Fluorescence

Model: EDX-8800G MAX XRF

Model: EDX-8800G MAX XRF

Simply the Best

The latest generation of detector: High-throughput count rate and ultra-low resolution.

Wider element detection range: Analysis covers elements from 9F (Fluorine) to 95Am (Americium) in the periodic table, and supports oxide analysis. Lower detection limit:

Capable of achieving concentration analysis in the range of 0.2 ppm to 99.99%. Composite target X-ray tube: Achieves better excitation effects for both light and heavy elements simultaneously.

Extra-large vacuum sample chamber: Adapts to the non-destructive testing of larger-sized samples.

One-click conversion between helium and vacuum testing environments: Meets diversified testing requirements.

Provides multiple data access interfaces: Enables compatibility with the LIMS (Laboratory Information Management System)

EDX8800G MAX Energy Dispersive Fluorescence Spectrometer - Materials Analysis Expert

The EDX8800G MAX can detect materials covering metals, ores, environmental samples, building materials, electronics, food products, cultural relics, etc. Its core application scenarios include composition analysis, quality control, safety compliance, scientific research and traceability, etc.

ESI EDX8800G MAX spectrometer is mainly applied in third-party laboratories and various places that require high-precision material composition analysis. The EDX8800G MAX focuses on the qualitative and quantitative analysis of major, minor, and trace elements or compounds in various materials. It can be widely used in the following fields: alloy materials, precious metals, iron ore powders, non-ferrous metals and powders, metallurgy, metallic and non-metallic mineral resources, refractory materials, refractory raw materials, titanium dioxide, gypsum, catalysts, ceramics, cement, lime, the glass industry, quartz, feldspar, calcite, clay, rock wool, soil, solid waste, dust removal ash, red mud, fly ash, rare earth permanent magnets, petroleum products, furnace slag, etc. It can conduct rapid qualitative and quantitative analysis of the chemical compositions of production raw materials and finished products, and has significant advantages such as being fast, accurate, non-destructive, efficient, and environmentally friendly. It does not require acid-base chemical reagents, which saves costs and reduces pollution.

Application

Alloy Composition Analysis:

Rapidly determine the elemental content in materials such as stainless steel and aluminum alloys.

Quality Control: Ensure that metal materials comply with industry standards (such as ASTM, ISO).

Scrap Metal Sorting: Identify the components in scrap metals to optimize the recycling process.

Mining and Geological Exploration:

Ore Grade Evaluation: Analyze the content of target elements in minerals.

Mineral Identification: Determine the composition of rock and mineral samples to assist in geological research.

Environmental Monitoring and Governance:

Soil/Sediment Analysis: Detect heavy metal pollution (such as lead, arsenic, cadmium).

Water Quality Testing: Screen for harmful elements in industrial wastewater.

Air Particle Analysis: Monitor the metal components in atmospheric dust.

Building Materials, Ceramics and Glass:

Cement Quality Control: Analyze elements such as calcium, silicon, and iron in raw materials.

Glass Manufacturing: Ensure that the proportion of oxides in the formulation meets the requirements.

Coatings and Paints: Detect lead or other restricted components.

Electrical Appliances and Consumer Goods:

RoHS/WEEE Compliance: Detect hazardous substances such as lead, cadmium, and mercury in electronic products.

Toy Safety: Ensure that plastic or coating materials comply with international safety standards.

Petrochemical and Energy Industry:

Fuel Sulfur Content Detection: Comply with environmental protection regulations (such as sulfur limits in diesel).

Lubricating Oil Analysis: Monitor wear metals (iron, copper) to predict equipment failures.

Catalyst Research: Evaluate the distribution and content of active components (such as platinum, palladium)

Archaeology and Cultural Relic Protection:

Analysis of Cultural Relic Materials: Identify the composition and origin of ancient ceramics and metal artifacts.

Restoration Assistance: Match the chemical composition of restoration materials with that of the original artifacts.

Pharmaceutical and Food Industries:

Drug Impurity Detection: Screen for heavy metal pollution in active pharmaceutical ingredients (such as in accordance with USP <232> standard).

Food Safety: Detect toxic elements in food (such as arsenic in rice and mercury in fish).

Scientific Research and Education:

Materials Science Research: Analyze the correlation between the elemental composition and properties of new materials.

Teaching Experiments: Used for practical teaching in disciplines such as chemistry and geology.

Jewelry and Precious Metals: Purity Identification:

Rapidly determine the fineness of precious metals such as gold, silver, and platinum (such as the content of karat gold).

Gemstone Treatment Detection: Identify traces of filling or dyeing treatments.

Nuclear Industry and Special Materials:

Nuclear Fuel Analysis: Detect the purity and composition of nuclear materials such as uranium and plutonium.

Radiation Shielding Materials: Analyze the distribution effect of elements such as lead.

Features

The EDX8800G spectrometer is accurate, fast, non-destructive, environmentally friendly and easy to learn. It is the preferred solution for the domestic substitution of imported instruments.

It can conduct composition analysis of both elements and oxides simultaneously.

The specially designed optical path and vacuum system greatly improve the testing sensitivity and accuracy for light elements (Fluorine (F), Sodium (Na), Magnesium (Mg), Aluminum (Al), Silicon (Si), Phosphorus (P), Sulfur (S)). A helium gas system can be optionally configured at the same time to enable the direct testing of liquid and powder samples.

There are eight optical path collimation systems, which can be automatically switched according to the size of different samples. It is also possible to test different positions of the sample and then calculate the average value, reducing the errors caused by sample inhomogeneity.

The high-definition built-in camera clearly displays the part of the sample being detected by the instrument.

It can be equipped with a sample spinning platform to increase the sample detection area and improve the testing accuracy and precision.

Specifications

Size: 650mm*600mm*900mm

Weight: 105Kg

Element analysis range:9F-95Am F-Am

Analyzable content range:0.2ppm- 99.99%

Detector:Original imported ultra-high resolution silicon drift detector

Multi - channel analyzer: Digital 4096 - channel analyzer, peak drift less than 0.5 channels (within 24 hours)

X - ray tube: Original imported high - power tube (high - power composite target tube is optional)

Sample types: Solids, liquids, powders, air filters

Automatic sampler: Standard with 10 positions, 12 - position and 14 - position options available

Collimator system: 8 groups with automatic adjustment

Filter system: 7 groups with automatic adjustment

Sample chamber: Air, vacuum, helium - filled (optional)

Size of the vacuum sample chamber: 360mm * 360mm * 60mm

Voltage: 220ACV 50/60HZ

Ambient temperature: - 10 °C to 35 °C

Optional configurations:

1 Sample spinning system

2 Helium gas filling system (One - click switching among vacuum, helium, and air states)

Size: 650mm*600mm*900mm

Weight: 105Kg

Element analysis range:9F-95Am F-Am

Analyzable content range:0.2ppm- 99.99%

Detector:Original imported ultra-high resolution silicon drift detector

Multi - channel analyzer: Digital 4096 - channel analyzer, peak drift less than 0.5 channels (within 24 hours)

X - ray tube: Original imported high - power tube (high - power composite target tube is optional)

Sample types: Solids, liquids, powders, air filters

Automatic sampler: Standard with 10 positions, 12 - position and 14 - position options available

Collimator system: 8 groups with automatic adjustment

Filter system: 7 groups with automatic adjustment

Sample chamber: Air, vacuum, helium - filled (optional)

Size of the vacuum sample chamber: 360mm * 360mm * 60mm

Voltage: 220ACV 50/60HZ

Ambient temperature: - 10 °C to 35 °C

Optional configurations:

1 Sample spinning system

2 Helium gas filling system (One - click switching among vacuum, helium, and air states)

Product Similar

XRF Mining Analyzer

Model:Compass 300

Manufacturer: ESI - China

Contact for quotation: 0765 259 545

Field lab performance meets the accuracy of your portable production/mining/soil product analyzer, on-site ore exploration, mine mapping, excavation and grade control industrial bench design more powerful more accurate and stable test performance ...

0765 259 545

Intermediate alloy measurement spectrometer

Model: XRF-EDX 9000A

Manufacturer: ESI - China

Contact for quotation: 0765 259 545

XRF energy dispersive X-ray fluorescence spectrometer Alloy measurement spectrometer -EDX9000 A Introduction Intermediate alloys are special alloys used to solve the problems of flammability, high melting point, difficulty in melting and easy separation of single elements. ..

0765 259 545

EDX-9000A PLUS XRF Spectrometer

Model: EDX-9000A PLUS XRF

EDX-9000A PLUS XRF Spectrometer--- Advanced Precious Metal Analyzer > Advanced high-performance XRF Precious Metal Analyzer-- Fast, Non-destructive, Super stable, highly precise >Completely non-destructive analysis , Minimum sample prepare needed >Fast results in 10 seconds >High performance Fast SDD detector can cover up to 45 elements simultaneously >No need for daily calibration reduce test time >Robust and solid, extremely user friendly >Extended application available for coating thickness analysis, precious metal analysis in liquid

0765 259 545

Solid Waste XRF Analysis Spectrometer -EDX8000B

Model: EDX8000B

Energy Dispersive X-ray Fluorescence S pectrometer Solid Waste XRF Analysis spectrometer -EDX8000B 1. Introduction Solid waste refers to the solid, semi-solid, and gaseous items or substances that have lost their original use value or although they have not lost their use value, they are...

0765 259 545

Film Thickness Meter EDX-8000T XRF Coating Thickness Tester /Electroplating Solution Analyzer

Model: EDX-8000T

0765 259 545

EDX8000T Plus plating thickness measuring device

0765 259 545

Compass 200 grain heavy metal XRF meter

Heavy metals in grains refer to heavy metal elements such as lead, cadmium, mercury, arsenic, and chromium contained in grains. When the content of these heavy metal elements in cereals exceeds standards, it will cause serious harm to human health

0765 259 545

Bench top XRF Oil Element Analyzer- EDX-9000E Simply The Best Advanced sulfur-in-oil analyzer Advanced metals-in-lubricant analyzer Advanced precision Advanced reliability and robustness Advanced software and data management

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR