Furnace M1200-20

-

169

-

0765 259 545

Model: M1200-20

Manufacturer: ZYLAB - China

Contact for quotation: 0765 259 545

Email: sales@yktech.com.vn

ZYLAB 1200°C Muffle Furnace for 3D Printing is a high-performance, cost-effective sintering solution designed for ceramic additive manufacturing. With precise temperature control and uniform heating, this mid-temperature furnace is ideal for sintering 3D printed ceramic components in research labs, universities, and industrial environments.

Model: M1200-20

Manufacturer: ZYLAB - China

Contact for quotation: 0765 259 545

Email: sales@yktech.com.vn

ZYLAB 1200°C Muffle Furnace for 3D Printing

Introduction

ZYLAB 1200°C Muffle Furnace for 3D Printing is a high-performance, cost-effective sintering solution designed for ceramic additive manufacturing. With precise temperature control and uniform heating, this mid-temperature furnace is ideal for sintering 3D printed ceramic components in research labs, universities, and industrial environments.

Equipped with a user-friendly 7″ touchscreen controller, a multilayer alumina fiber chamber, and a top-mounted exhaust system, this furnace ensures clean processing, efficient heat distribution, and safe operation. Multiple chamber sizes are available to support various experimental needs.

Key Features

- Max Temperature 1200°C: Working range: RT to 1100°C—suitable for mid-temperature sintering of 3D printed ceramics.

- 7-Inch Smart Touchscreen Controller: Intuitive UI, real-time temperature tracking, and programmable temperature curves to eliminate redundant manual settings.

- 30-Segment Programmable Control: Fully automatic, customizable heating profiles for precise thermal treatment.

- High-Efficiency Ceramic Fiber Chamber: Constructed with multilayer alumina insulation for rapid heating and energy savings.

- Premium Heating Components: Equipped with corrosion-resistant alloy heating wires to minimize contamination and extend service life.

- Top Exhaust Chimney: Efficiently removes fumes and volatiles—ideal for wax burnout, ashing, and other lab applications.

- Dual-Layer Steel Housing with Cooling Fan: Keeps exterior temperature below 50°C, ensuring operator safety and extended equipment lifespan.

- Compact, Lightweight & Energy Efficient: Designed for lab benches or small-scale production use; a practical tool for R&D or ceramic sintering in industrial settings.

- Customizable Chamber Sizes (Optional): Available in multiple volumes to suit different workflows and material requirements.

Applications of Muffle Furnace for 3D Printing

-

Sintering of 3D printed ceramic parts

-

Debinding of ceramic green bodies

-

Wax burnout and ashing processes

-

High-temperature material testing

-

General heat treatment in research and small-scale production

Technical Specifications of 1200°C Muffle Furnace for 3D Printing

| Model | M1200-15 | M1200-20 | M1200-30 | M1200-40 |

| Working voltage | AC 208 – 240V, 50/60 Hz (according to requirement) | |||

| Max. Power | 3KW | 4KW | 9KW | 15KW |

| Maximum Temperature | 1200°C (for ≤1 hour) | |||

| Continuous Working Temp | 1100°C (continuous) | |||

| Max Heating Rate | ≤20°C/min | |||

| Chamber Size | 150 × 150 × 200 mm | 200*200*300mm | 300*300*400mm | 400*400*500mm |

| Overall Dimensions | 390 (W) × 600 (H) × 430 (D) mm | 650(W)*520(H)*600(D)mm | 950(W)*1400(H)*870(D)mm | 1100(W)*1650(H)*1050(D)mm |

| Temperature Controller |  |

|

||

| Temperature Accuracy | ±1°C | |||

| Heating Element |  |

Mo-doped Fe-Cr-Al alloy heating wire | ||

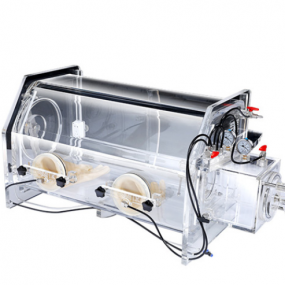

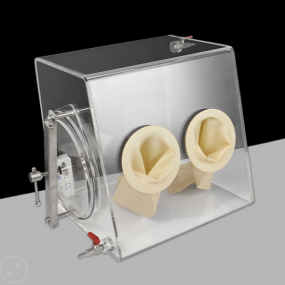

| Atmosphere Protection Box(Optional) |  |

Designed to create a controlled atmosphere inside the chamber. Prevents oxidation, contamination, and undesired reactions during heating. Customizable sizes available. | ||

| Net Weight | 40 kg | 60 kg | 160 kg | 260 kg |

| Safety Notice |

|

|||

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR