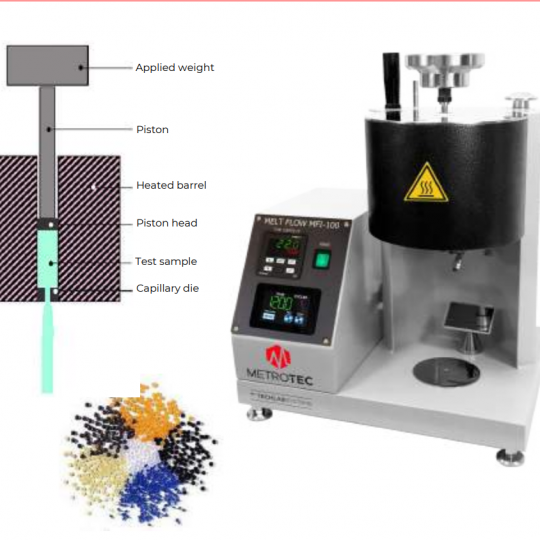

Gravimetric Melt Flow Indexer model MFI-100

-

323

-

0765 259 545

Basic plastometer for the determination of the melt index in thermoplastic materials by the gravimetric method.

- Standards:

ASTM D1238, DIN 1133, EN 1133, ISO 1133, UNE 1133.

PRINCIPLE OF THE MFI TESTS The melt flow index measurement is performed by means of a Melt Flow Tester, which operates with a constant pressure, exerted by a constant force due to a known weight on a capillary tube whose area remains constant. The ASTM-D1238 standard is commonly used to perform this operation. The melt flow index (MFI) is a measure of the flow capacity of the resin under controlled conditions and can be easily measured with an equipment called a plastometer, using very low deformation rates, a temperature and a dead weight applied on the piston according to the Standards ASTM D 1238, ISO 1133 ...

This variable is inversely related to viscosity and molecular weight (MW), that is, as the resin's fluid index increases, a decrease in viscosity and molecular weight. For Manual test (Method A - Gravimetric)

• Kit includes all standard work-cleaning tools, piston and nozzle.

• Standard temperature range up to + 325ºC (*) with resolution of ±0.1ºC

• Digital Stopwatch: with a range of up to 9999 seconds • Automatic sample cutting

• 7 chrome and polished weights included in the standard supply: 1.2 Kg - 2.16 Kg - 3.8 Kg - 5 Kg - 5 Kg - 6.6 and 10 Kg

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR