VICAT-HDT Softening Test Apparatus

-

605

-

0765 259 545

- Standards: ASTM D 648, ASTM D 1525, ISO 75-2, ISO 306, DIN 53460, DIN 53461, UNI EN ISO 75-2, UNI EN ISO 306.

- Applications:

Automobile panels.

Tubes and plastic pipes.

Automotive dashboards.

- Description

Laboratory test equipment for the determination of the softening point VICAT and the bending temperature HDT in thermoplastic materials.

APPLICABLE STANDARDS ASTM D 648 - ASTM D 1525 - ISO 75-2 - ISO 306 - DIN 53460 - DIN 53461 - UNI EN ISO 75-2, UNI EN ISO 306

- GENERAL INFORMATION The VHDT-30 tester is specifically designed to be used in the Quality Control Department for the determination of the VICAT softening point and the HDT flex temperature in plastic materials.

- PRINCIPLE OF THE TEST The VICAT softening point is the temperature at which a 1mm 2-section flat needle penetrates a sample at a depth of 1mm HDT is the flexural temperature under load, expressed as the temperature at which the sample reaches a certain arrow.

• Robust construction

• Interior of the bathroom in stainless steel. The interior volume design is studied in a way that ensures a perfect thermal change, both heating and cooling.

• Temperature control by PID and Pt-100 sensor

• Working temperature: from room to +250 ºC

• Resolution: +/- 0.1 ºC

• Accuracy: +/- 0.2 ºC

• Heating rate: 120ºC / Hour and 50ºC / hour (configurable)

• Equipped with 3 Pt100 temperature probes (one for each test station)

• Test stations equipped with linear displacement sensors, with a range of 10 mm and resolution of ± 0.01 mm

• Set of 16 weights for each test station included: 2 of 5 g, 2 of 10 g, 2 of 15 g, 1 of 25 g, 1 of 50 g, 1 of 100 g, 2 of 200 g, 1 500g, 1 750g, 1 845g and 2 2000g (16 weights per station x 3 = 48 weights total)

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

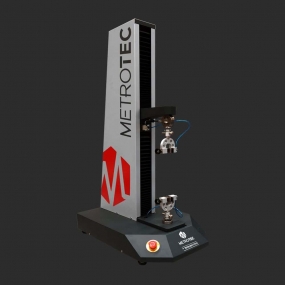

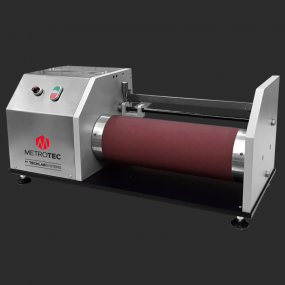

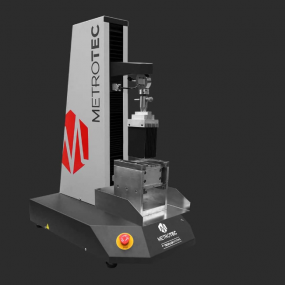

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR