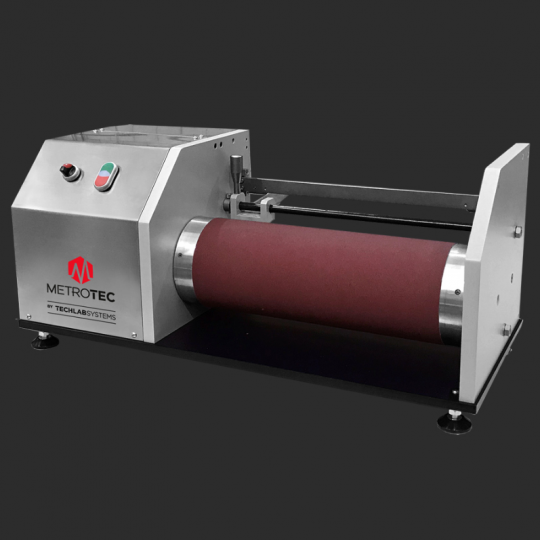

Abrasion Tester AT-50

-

135

-

0765 259 545

- Description

Laboratory equipment to determine the resistance to wear by abrasion of standardized samples of Rubber, Plastics, Leather...

- Standards: ASTM D 5963 – ISO 4649

APPLICABLE STANDARDS ASTM D 5963 - ISO 4649 TEST MODE

The sample to be tested is cylindrical in shape with a diameter of 16 mm, it is subjected to rubbing against an abrasive cloth (standardized), which covers a cylinder, under pressure that is also standardized.

The cloth holder cylinder rotates at a speed of 40 revolutions per minute, and the specimen is in continuous contact with the abrasive for the equivalent of 40 linear meters, after which the specimen holder separates from the abrasive cloth automatically, removing the contact.

The specimen holder arm is provided with a micrometric screw to adjust the position of the specimen. The weight of this arm provides a pressure on the specimen of 0.5 Kg. A special counterweight that can be placed on the arm allows the pressure to be increased up to 1 Kg when very resistant materials are to be tested.

The amount of wear of the tested sample is determined by calculating the difference in weight of the sample before and after the test. It is advisable to have a Precision Balance with reading every 0.001 g)

• Instant return of the carriage to its initial test position.

• Speed: 40 Laps/minute

• Friction per turn: 40 cm

• Total friction: 40 meters

• Specimen feed: 4.2 mm per turn

• Micrometric screw with divisions every 0.1 mm.

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

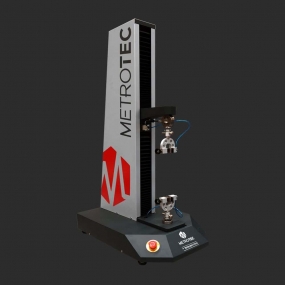

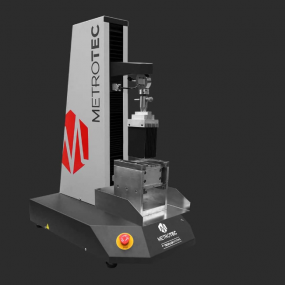

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR