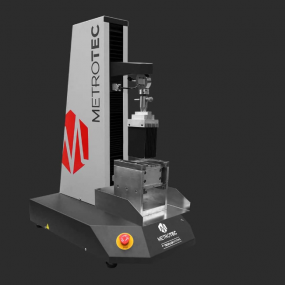

Electromechanical Material Testing Machine MTE-1L (1 kN)

-

178

-

0765 259 545

Electromechanical Material Testing Machine MTE-1L (1 kN)

MTE-1L Specifications:

- Capacity: 1 kN

- Force Resolution with 5kN Load Cell: 0.01 N

- Measured Force Accuracy: ≤ ± 0.5%

- Displacement Resolution: 0.001 mm

- Travel Accuracy: ≤ ± 1%

- Mobile Crosshead Travel: 800 mm

- Separation Between Column and Grips Adapter: 150 mm

- Range Standard Test Speeds: 0.5 – 1000 mm/min

- Accuracy of Test Speed: ≤ ± 1%

- Maximum Return Speed: 1000 mm/min

- Spacing Between Fixings (Adapters): 800 mm

- Electric Supply: 220V / 50Hz - 110V/60Hz (single-phase)

- Approximate Power: 400 W

- Working Ambient Temperature and Humidity: 10 ºC ~ 35 ºC

- Dimensions (Test Frame): 420x670x1250 mm

- Net Weight: 60 kg

- Dimensions (Wooden Packaging): 550x870x1550 mm

- Gross Weight: 110 kg

Product Similar

Volumetric Melt Flot Flow Indexer model MFI-500-AUTO

- Gravimetric and volumetric method.

- Computerized by Melt Flow Index Software (Mini PC included in the supply).

- The Testing Software allows testing and determines the flow rate.

- Automatic sample cutting.

- PID temperature controller (holding ± 0.1ºC).

- Programmer of time and number of cutting cycles.

- Equipment prepared to work with corrosive materials such as PVC.

- The kit includes all working and cleaning tools, piston and standard nozzle.

- Standard temperature range up to +325 ºC (*) with resolution of ± 0.1ºC.

- Digital stopwatch with a range of up to 9999 seconds.

- 7 Chromed and polished weights included in the standard supply: 1.2 Kg – 2.16 Kg – 3.8 Kg – – 5 Kg – 5 Kg – 6.6 and 10 Kg (The weight of 21.6 kg is achieved by combining the weights of 5kg, 6.6kg and 10kg).

- Motorized automatic weight loader.

- RS-232 output interface with converter to USB.

- To calculate the Melt Index in the MFI-500/AP model using the Gravimetric method, it is necessary to weigh the extruded material with a - resolution of 0.001 g, therefore we recommend using a precision balance.

- CE marked.

Standards

ASTM D1238, DIN 1133, EN 1133, ISO 1133, UNE 1133.

0765 259 545

VICAT-HDT Softening Test Apparatus

- Standards: ASTM D 648, ASTM D 1525, ISO 75-2, ISO 306, DIN 53460, DIN 53461, UNI EN ISO 75-2, UNI EN ISO 306.

- Applications:

Automobile panels.

Tubes and plastic pipes.

Automotive dashboards.

- Description

Laboratory test equipment for the determination of the softening point VICAT and the bending temperature HDT in thermoplastic materials.

0765 259 545

- Description:

Basic plastometer for the determination of the melt index in thermoplastic materials by the gravimetric method.

- Standards:

ASTM D1238, DIN 1133, EN 1133, ISO 1133, UNE 1133.

0765 259 545

Rebound Resilience Tester RB-10D

- The test apparatus allows to determine the rebound percentage of the hammer measured over its height of fall. The test piece used is circular with a diameter of 44.6 mm and a thickness of 6 mm. Failing this, a round or square piece of rubber can be used, measuring approximately

• Power: 0.5 Joules – 5 Kg. cm

• Bounce rate: 0-100%

• Angle of fall: 90º

- Standards ISO 4662 – DIN 53512 – ASTM D 1054

0765 259 545

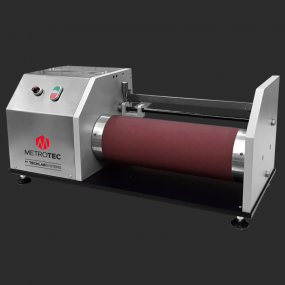

Abrasion Tester AT-50

- Description

Laboratory equipment to determine the resistance to wear by abrasion of standardized samples of Rubber, Plastics, Leather...

- Standards: ASTM D 5963 – ISO 4649

SCITEK - China

SCITEK - China EBP - China

EBP - China SOOHOW - China

SOOHOW - China ZD Instrument - China

ZD Instrument - China Yante

Yante JJ-Test

JJ-Test Labthink

Labthink Hunterlab

Hunterlab EURPING - China

EURPING - China Wisdom - China

Wisdom - China ZYLAB - CHINA

ZYLAB - CHINA ERKAYA -

ERKAYA - Novotest - Ukraine

Novotest - Ukraine Moderner - China

Moderner - China GBPI - China

GBPI - China Milkotester - Bulgaria

Milkotester - Bulgaria LAMY RHEOLOGY

LAMY RHEOLOGY  Emco

Emco GESTER - China

GESTER - China GonDo - Taiwan

GonDo - Taiwan Agri-instrument - China

Agri-instrument - China CHN - China

CHN - China PNTOO - China

PNTOO - China TESTER SANGYO

TESTER SANGYO FRU - China

FRU - China Rucca - China

Rucca - China HSIANG TAI - CHINA

HSIANG TAI - CHINA FYI - China

FYI - China Boxun - China

Boxun - China Linshang - China

Linshang - China Hanon - China

Hanon - China PCE - UK

PCE - UK  Biuged

Biuged IRIS

IRIS ACEY - China

ACEY - China 3NH

3NH XS Instruments

XS Instruments Doser

Doser OPTIKA - ITALY

OPTIKA - ITALY Great Safe

Great Safe Kett

Kett Mitutoyo

Mitutoyo Cometech - Taiwan

Cometech - Taiwan Veego

Veego COPLEY SCIENTIFIC

COPLEY SCIENTIFIC  Exotek

Exotek Total Meter

Total Meter PNShar

PNShar Radwag

Radwag SH Scientific

SH Scientific X-Rite

X-Rite Metrotec

Metrotec Hach

Hach Hanna

Hanna Endecotts

Endecotts TRINAMIX

TRINAMIX HMKTEST

HMKTEST PackTest Machines Inc

PackTest Machines Inc CHAO QIANG - CHINA

CHAO QIANG - CHINA Sartorius - Germany

Sartorius - Germany SIKA - Germany

SIKA - Germany Ohaus

Ohaus SUN SCIENTIFIC

SUN SCIENTIFIC Aczet

Aczet Trace2o - UK

Trace2o - UK Glas -Col - USA

Glas -Col - USA Beijing

Beijing ATAGO – JAPAN

ATAGO – JAPAN TECHLAB SYSTEMS

TECHLAB SYSTEMS ESI

ESI RJS - USA

RJS - USA Kruss

Kruss Lumex Instruments

Lumex Instruments ELECTROLAB

ELECTROLAB  Haida

Haida Horiba

Horiba Konica

Konica Datacolor

Datacolor CRYSTE

CRYSTE Uni-T

Uni-T Oxford Instruments

Oxford Instruments Fuzhou Furi - China

Fuzhou Furi - China Alpha MOS

Alpha MOS  Drick

Drick FPInnovations - Canada

FPInnovations - Canada Memmert

Memmert 3M

3M Advantec

Advantec Newstar

Newstar ANTON PAAR

ANTON PAAR